Reduces torque and drag.

Provides unmatched protection from casing, riser, and drill string wear.

WWT Non-Rotating Protectors (NRPs) are the industry’s leading mechanical torque and friction reduction tool, designed to improve drilling efficiency, protect casing and risers, and extend drill string life. For more than 30 years, WWT International has partnered with operators worldwide to overcome complex downhole challenges including excessive torque, drag, casing wear, riser wear, heat checking, drill pipe buckling, and energy loss caused by wellbore friction.

Often referred to as drill pipe rubbers, WWT’s NRPs combine extensive engineering with field-proven reliability, offering operators a fully supported, performance-optimized solution for all well types.

Key Benefits:

- Reduce torque and drag — improve drilling efficiency and energy transfer to the bit

- Prevent casing and riser wear — isolate tool joints to eliminate direct metal-to-metal contact

- Mitigate heat checking and pipe damage — extend the life of tubulars and drilling components

- Lightweight clamp-on design — easy to install, adds negligible weight, and maintains derrick racking capacity

- Fast installation — each NRP can be installed in just over one minute, online or offline

- Compatible with Managed Pressure Drilling (MPD) and Rotating Control Devices (RCDs)

- Robust, versatile design — ideal for cased, open hole, and deepwater riser applications

Engineering Support and Well Modeling Expertise

A complementary well analysis with torque & drag modeling backs every WWT NRP deployment. Our engineers evaluate your wellbore conditions and provide a custom placement recommendation to identify where NRPs will deliver the greatest benefit. This modeling compares torque and drag with and without NRPs, ensuring optimal protection and performance.

WWT can also provide casing wear modeling and ECD impact analysis to help operators make fully informed decisions.

Contact WWT to discuss your application further. Download and complete WWT’s well data sheet, which details info required for a complimentary analysis.

Casing Wear and Heat Checking Mitigation Benefits

WWT NRPs have an outer diameter larger than the tool joint, creating a protective standoff that prevents tool joints from contacting the casing. By isolating rotation, NRPs eliminate casing wear, heat checking, and costly damage that can lead to repairs, tiebacks, or downtime.

Installing NRPs at high-contact zones ensures maximum casing protection throughout every hole section.

Torque Reduction Benefits

WWT NRPs dramatically reduce rotational friction, up to 90%, by creating a hydrodynamic fluid bearing between the drill string and NRP. The NRP’s patented inner sleeve geometry allows drilling fluid to circulate through the sleeve, minimizing friction even at low RPMs and in all drilling fluids.

The result: lower torque, higher energy transfer to the bit, and improved drilling performance in any environment.

Drag Reduction and Buckling Mitigation Benefits

WWT’s Super Slider Protectors (Model SS3) feature low-friction outer material that minimize sliding friction (drag) and allow the drill pipe to rotate freely within the stationary sleeve.

- Increases slack-off weight

- Decreases pick-up weight

- Reduces drill string buckling by shortening the unsupported column length

Field results and finite element modeling confirm that WWT NRPs effectively reduce vibration, torque, drag, and lockup, allowing for smoother weight transfer and more efficient drilling.

Riser, LMRP and Loop Current Protection

WWT NRPs are also proven in deepwater drilling, offering riser, wellhead, and LMRP protection.

They maintain proper standoff between the drill string, riser, flex joint, and BOP, preventing wear and allowing operations to continue safely, even in strong loop currents where drilling might otherwise be suspended.

Design & Installation Advantages

- Clamp-on design enables fast, secure installation directly on drill pipe joints

- No added connections or stand length — maintain derrick racking capacity

- Negligible additional weight versus heavy sub-type protectors

- One-minute installation per NRP assembly using a torque wrench

- Reusable placement — maintain optimal protection without removing NRPs after each trip

- Qualified Field Application Specialists oversee installation, inspection, and removal

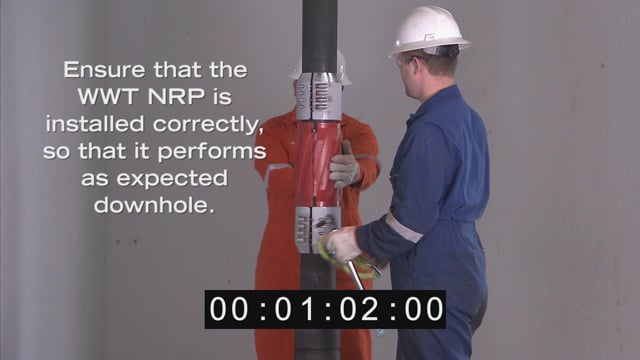

Installation

Each NRP assembly consists of a hinged elastomer or low-friction polymer non-rotating sleeve bonded to an internal metal reinforcement cage. One hinged aluminum "collar" acting as a thrust bearing is installed on each side of the sleeve, inverted with respect to the other. The collars generally consist of 3 to 6 bolts each depending on the model and torqued to specification using a calibrated torque wrench. Each NRP can be installed in just over one minute, watch our installation video for more details.

Proven, Reliable and Field-Tested

With decades of global success, WWT NRPs are the most widely used downhole torque and drag reduction tools in the world. From onshore wells to deepwater riser applications, WWT’s solutions deliver measurable results, improving efficiency, reducing wear, and extending tool life.

Contact WWT International to discuss your next well application and request a complimentary NRP placement analysis.

Videos

Go to Case Histories and filter Product to 'Non-Rotating Protectors' for more information: https://www.wwtco.com/solutions/case-histories/