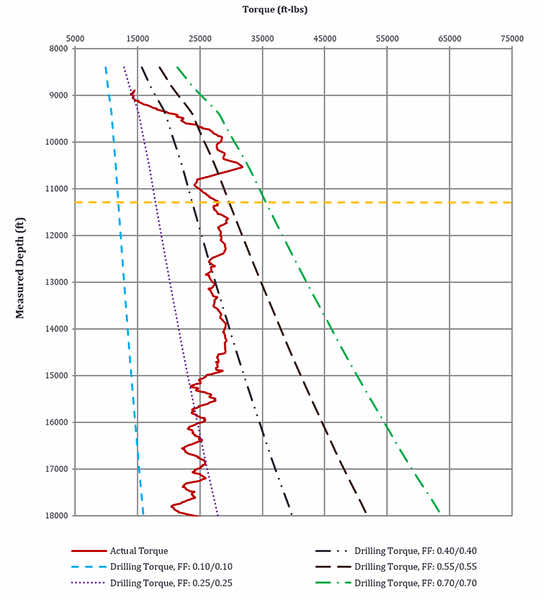

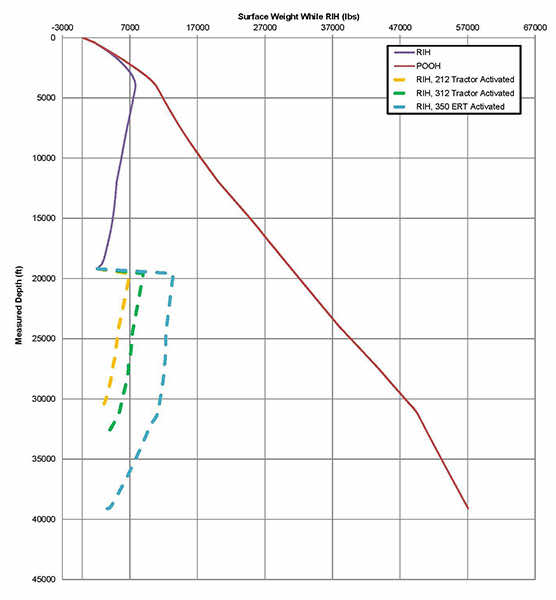

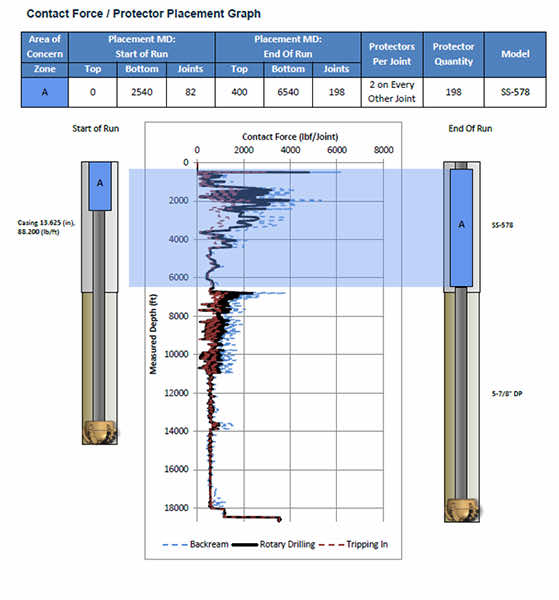

WWT’s experienced engineering team runs Torque and Drag analyses at no cost to determine appropriate applications and the optimal location for WWT products. Numerous modeling methods, including soft string, stiff string, 3D beam element, and FEA are utilized to provide technical support to customers.