WWT Silencer

Case StudyBHA Vibration Reduction in 3-Mile Lateral Using Field-Installable Silencer

|

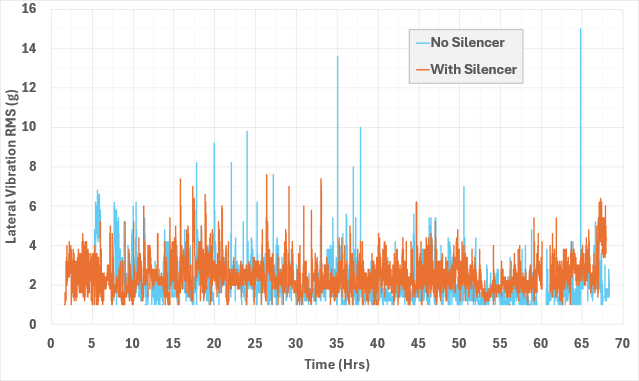

Client Challenge An operator in the Delaware Basin faced challenges with shock and vibration, which were causing failures in the MWD tools and the bit. The operator needed a solution to mitigate these issues and prevent equipment failure while drilling three-mile laterals through an abrasive formation.

Our Solution WWT’s Silencer, featuring an improved sleeve design with low-friction blades, was installed directly behind the motor to target vibrations near the MWD tools. The design modifications also included improvements for easier field installation. The Silencer was used for a final run to total depth (TD), starting at a depth of 16,907 ft and ending at 22,815 ft MD, for a total run length of 5,894 ft. at 7,600 ft TVD.

Results

|

|

PDF format for download here: WWT Case History NRSA Horizontal Permian 13239